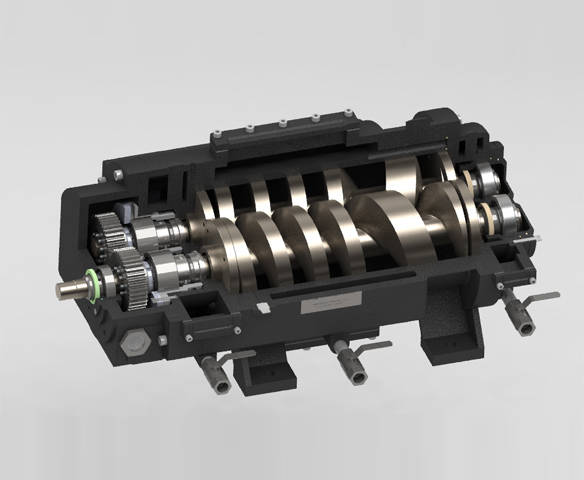

product description

SDP variable pitch screw vacuum pump, also known as dry screw vacuum pump, is a working chamber composed of a pair of parallel spiral rotors and a pump body. It is processed by a five axis linkage composite machining center, and there is no friction between the two screw rotors and the pump body, while maintaining a certain gap. Multiple sealed chambers are formed between the two rotors and the pump body. When the rotors rotate synchronously and at high speed in the pump housing through a gear, the gas in each sealed chamber is continuously pushed from the inlet end to the exhaust end, producing suction and exhaust effects.

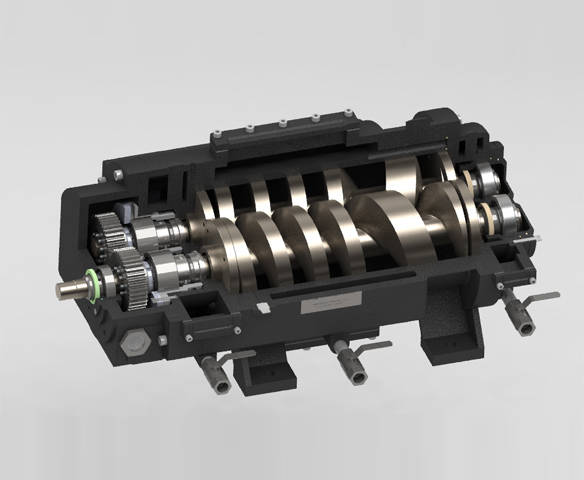

The working chamber of the screw pump is gap sealed and oil-free, making it an environmentally friendly vacuum equipment. Therefore, the dry screw pump can extract gases containing a large amount of water vapor and a small amount of dust, with high ultimate vacuum, low power consumption, and advantages such as energy saving, consumption reduction, and maintenance free. Especially in situations where oil-free cleanliness is required in the semiconductor and electronic industries, as well as in solvent recovery processes in chemical and pharmaceutical industries, it has incomparable advantages.

Screw vacuum pump is a substitute product for traditional water ring vacuum pump, water jet vacuum pump, reciprocating vacuum pump, slide valve vacuum pump, rotary vane vacuum pump and other vacuum pumps. The upgrading and replacement of this product can effectively eliminate sewage discharge in the vacuum process of the pharmaceutical and chemical industry, facilitate the recovery of exhaust gas solvents, and effectively reduce oil vapor pollution of slide valve vacuum pump and rotary vane vacuum pump, thereby reducing equipment maintenance costs.